Grease Trap Cleaning, Installation & Maintenance For Commercial Kitchens

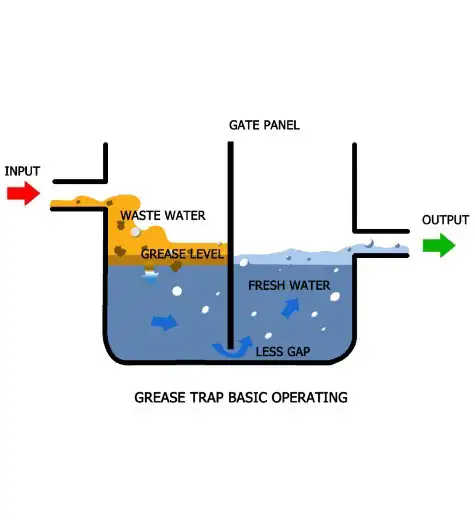

The purpose of a grease trap, specifically grease traps for commercial kitchens is to collect and reduce the amount of fats, oils and greases that enter the main sewer. At VSS, we are experts providing a range of grease trap services including installation, cleaning and regular maintenance to ensure your kitchen meets food hygiene regulations.

Kitchen Grease Trap Legal Duties: Building Regulations Part H Compliance

The increase of food outlets and dining out in the UK has led to an unprecedented rise of Fats, Oils and Greases being deposited into our sewer systems. Clearing those blockages and cleaning up properties flooded, after pollution incidents because of blocked sewers costs the UK more than £80 million per year according to the British Water figures.

The 2000 Building Regulations Part H, (amended 2002), advises that the requirement for an adequate drainage system is to minimise the risk of blockage or leakage.

Commercial kitchens and hot food premises should be fitted with a grease trap and should comply with BS EN 1825-1. Commercial grease trap systems should also be designed in accordance with BS EN 1825-2, demonstrating effective means of grease removal. BS EN 1825 is the European standard for commercial gravity grease traps and separators. Other effective means include mechanical grease removal equipment and biological or bacterial dosing systems which break down grease. and designed in accordance with BS EN1825-2 or other effective means of grease removal. BS EN1825 is the European standard for commercial gravity grease separators. Other effective means include mechanical grease removal equipment and biological or bacterial dosing systems which break down grease.

TR19 Grease and Food Hygiene Regulations

The Food Safety and Hygiene England Regulations 2013 and European Regulation (EC) 2013 and European Regulation (EC) no.852/2004 set out general hygiene rules that apply to all registered and approved food businesses including structural requirements and the implementation of procedures based on hazard analysis and critical control point (HACCP) principles. The regulation sets out objectives for “good hygiene practices” to protect food safety and consumers. This includes ensuring that grease is not allowed to build up and that premises and equipment are cleaned regularly to remove grease and dirt.

Grease Trap Cleaning

Grease traps require frequent maintenance, including regular grease trap cleaning, so the collected Fat, Oil and Grease (FOG) can be emptied and removed from the site by our licensed staff. Our grease trap cleaning team provides reliable and efficient cleaning services, ensuring that your grease trap functions correctly and your kitchen complies with health and safety regulations.

We also offer grease trap installation services, which we’ll access your kitchen’s needs and install the right type of grease trap for your business. With our expertise, we can advise you on the best solution for your kitchen.

Get in touch with us today for more information about our grease trap cleaning, installation services and ongoing maintenance for commercial kitchens. Our grease trap installation and cleaning experts are on hand to answer any questions and provide a quote that suits your business’s needs.

Commercial Kitchen Grease Removal Units

These require frequent maintenance, which will include emptying the collection container, cleaning of wiper blades and valves, and then the cleaning of the filter basket/ strainer baskets. In house cleaning is often required, VSS can train in house staff on how best to do this. This should be taken into account when planning the type of FOG system used and the ongoing cost of maintenance.

Dosing Systems

The dosing systems require fluid system refills, while others can be calibrated to automatically top-up, either at regular intervals or by monitoring the volume of discharge from the kitchen. Systems will also require regular refill and testing by VSS, which depending on the system used will normally be done monthly, quarterly or six monthly.